An ounce of prevention goes a long way.

By Layne Simpson

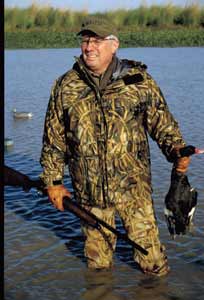

With more than 50 boxes of shells fired, the author's 20 gauge Beretta never malfunctioned, but when it became a bit sluggish, a small amount of oil applied to its action put it back into business. |

When the autoloading shotgun was beginning to catch on among hunters at the turn of the 20th century, it was predicted that a shotgun capable of loading itself was such a wonderful idea it would eventually make all other types of shotguns obsolete.

In looking back it is not difficult to see why such a prediction was made. At the time the pump gun was the answer to those who worshiped at the altar of firepower but it required interaction from the shooter from shot to shot. On the other hand, the semiautomatic fired a shot with each pull on its trigger and it kept on filling the sky with lead until the pheasant or duck fell from the sky or its magazine was empty.

Hunters also began to discover that the self-loader softened recoil a bit when compared to the single-shots and doubles they were accustomed to shooting. As it turned out, the crystal ball used by those who dared gaze into the future was at least half right--a shotgun that feeds shells automatically is a wonderful idea and it is incredibly popular among hunters and clay target shooters today€¦but it has yet to make other types of shotguns obsolete. If nothing else, the self-shucker has been and always will be a controversial shotgun with one side declaring it unreliable and downright unsporting while the opposite team has long touted it as the best thing to come along since smokeless powder.

Down through the years the autoloader has sometimes been described as unreliable in the field and while this is true of those of poor quality or questionable design, the really good ones will keep on ticking as long as they are properly cared for. On a recent duck hunt and dove shoot in Argentina, I fired over 50 boxes of 20-gauge shells in a field grade Beretta AL391 without cleaning it.

Along about round number 1350, its bolt began to travel to and fro a bit sluggishly but up to that point the gun had not malfunctioned a single time. I had no oil with me in the field but as I field-stripped the gun I noticed just a trace inside its magazine cap. Rubbing my finger inside the cap and then transferring just a tiny dab of oil to the action bar of the gun put us back in business for the rest of the day.

On another shoot in Argentina I fired 4175 rounds in a 20-gauge Beretta AL391 Teknys. It was cleaned at the end of each day and it malfunctioned only twice during the entire shoot; one of those times was due to a faulty shotshell primer.

I mention those two autoloaders because they are what I have used recently but others have proven equally reliable in my hands. I have one of the very first Remington Model 11-87 shotguns built when the gun was introduced almost 20 years ago. I have shot it a lot and can count its number of malfunctions on one hand with a finger or two left over. The only part I have replaced is a rubber o-ring--it broke during a duck hunt in Uruguay, yet the gun continued to function perfectly.

Other semiautomatics in my life that have seldom if ever let me down are a Browning Gold, a Benelli M2 Field, a Remington Model 1100, a pair of Franchi 48ALs in 20 and 28 gauge and a 20 gauge Browning A5. I am sure other reliable autoloaders are out there; I just haven't gotten around to trying them yet.

Modern autoloaders (like this Remington 11-87) are easily field stripped for cleaning. |

An important rule to remember here is a clean autoloader is a happy autoloader, and the happier it is the less likely it is to malfunction. Regardless of the type of shotgun I am shooting, I clean it thoroughly after each hunt or clay target session. That, along with the fact that I seldom shoot anything but autoloaders of proven design, goes a long way toward explaining why I seldom experience malfunctions. Cleaning one is so easy there is no good excuse for not doing it on a regular basis and if you concentrate your efforts on two or three areas, you and old Betsy should live together happily ever after.

Cleaning the entire bore of a shotgun barrel is important but a filthy chamber is the part that can cause a semiautomatic shotgun to malfunction, so be sure and scrub it vigorously with a brass brush dipped in solvent after every shooting session. Half a paper towel wadded and pushed through the bore with a cleaning rod finishes up the job.

Then we have the action. Propellant fouling from shotshells along with field debris such as bits of grass, weed seeds and dust can accumulate inside the receiver and tie up the innards of a gun enough to cause it to refuse to shoot. The fire control system of the typical modern autoloader is easily removed by pushing out one or two crosspins from its receiver. With that done, the bolt and its action bar are easily removed and this clears the way for cleaning those parts as well as the interior of the receiver.

Various aerosol degreasers do a great job of blasting out the crud. Before reassembling the action, apply an extremely thin layer of lube to any moving part that shows evidence of metal-against metal contact. And when I say an extremely tiny dab, I mean lightly coat your finger with just a trace of lube and apply it to the moving part; in this case too little is better than too much because an excessive amount of lubricant serves no purpose other than attracting dirt and dust. Another reason for using gun oils sparingly is the viscosity of some will thicken at low temperatures and this case cause a gun to become sluggish during a cold weather hunt

This is about it for a recoil-operated shotgun but gas guns have a valve that bleeds off excessive propellant gas not needed to operate the action and it causes fouling to accumulate on the magazine tube and other parts located beneath the forearm. The longer the fouling remains there the more difficult it is to remove so as soon as possible after each shooting session is the time to do it.

A good bore cleaning solvent and paper towels will handle the fouling if it is relatively fresh but if it has been allowed to accumulate and harden for quite a long time, 0000-grade steel wool dipped in solvent and powered by elbow grease may have to be used. After removing the forearm, clean everything in sight, including inside the gas cylinder attached to the bottom of the barrel and all parts associated with it.

As a rule, no lube is needed here but if you hunt a

lot in wet weather it's not a bad idea to lightly coat everything with a rust inhibitor. Follow these steps and your autoloader should keep on autoloading for a very long time.